Blog

Scale inhibitors aren’t effective with Espresso machines

This article is reprinted with permission. It was originally published by the Espresso Service Network

If you sell coffee products, water treatment should be on your list of high priorities.

If you are like most espresso business owners, you will or will be choosing between a Reverse Osmosis (RO) or Softening system as the foundation for your water treatment. If you choose a RO system and have extremely hard water, you may need a softening system as well. Next, will be the filters you use to address the more specific qualities of the water feeding your espresso machine but you can pass on a scale inhibitor.

Overview of Water Filtration

There are several types of water filters used in the coffee industry, but the basic ones are scale inhibitors, sediment filters, and carbon filters.

Carbon filters are designed to eliminate the taste and odor of chlorine or chloramine which many towns and cities use to kill bacteria typically found in water. Everyone should use a taste and odor filter if they are selling coffee beverages.

Sediment filters are designed to filter out large particles that are not dissolved in the water like sand or other foreign material.

Scale inhibitors are made to discourage minerals such as calcium and magnesium from crystalizing in your brewer’s tank and forming deposits that will block passages and envelope heating elements.

Scale Inhibitors Work for Coffee Brewers

A scale inhibitor slowly releases a media such as polyphosphate into the tank of your brewer. The medium may coat the sides of your tank or adhere to water molecules to inhibit them from crystalizing. When you operate your coffee brewer the minerals in your water have nothing to attach to. Scale inhibitors are made for coffee brewers which have tanks that evacuate, meaning water comes in and then goes out.

It is important to note that scale inhibitors can dramatically reduce the process of scale build-up in your coffee brewer, but they are not one-hundred percent effective and most importantly they do not work on espresso machines. For your coffee equipment, you have the option of purchasing a standalone scale inhibitor or one that is imbedded with your carbon, taste and odor, filter. There are several good brands and models available. It is best to speak with your service provider before hand to determine which manufacturer they carry to avoid purchasing an off brand.

Scale Inhibitors Do Not Work on Espresso Machines

The purpose of a steam boiler in an espresso machine is to produce heat at a temperature so high that it will yield steam. Unfortunately, the high temperature creates a damaging effect on the medium delivered to your boiler by your scale inhibitor.

This extreme heat causes the medium to liquefy and settle at the bottom of your steam boiler. The scale remains in your boiler still looking for things to cling to like your heating element and boiler walls but now, you and your espresso service technician will have the sludge (looks a lot like icing) of the polyphosphate to contend with as well.

Even if you own a newer espresso machine with a boiler renewal, the boiler is never drained enough to remove the polyphosphate at the bottom and it certainly does not remove the minerals that have already adhered inside the boiler. You may get some minerals out by renewing your boiler but not enough to prevent build-up. If you are an espresso machine owner, the best way to protect your machine from scale is to prevent it from ever entering your boiler

The Best Place to Buy Water Treatment

Like most service companies, the Espresso Service Network provides a basic softening and filtration system to protect your machine from scale build up. Your machine’s warranty will void if minerals are found present in your espresso machine.

If you did not receive a system with your equipment, you’ll want to speak with your service technician as soon as possible to discuss not only the water treatment options that are available to you but also the ones that fit your personal budget. A tip to make your life a whole lot easier is to purchase your water products from your service technician. In many cases, when something goes wrong with your brewer or espresso machine it can be traced to a clogged or malfunctioning filter. If your espresso service provider handles your water treatment, their technician will be able to fix it on the spot and you will not have to pay for another service company to come out.

Irregular Decaf Pours – sometimes

This article is reprinted with permission. It was originally published by the Espresso Service Network

Have you ever noticed your coffee especially your decaf pouring and looking very disappointing? If you have, you are not alone. The obvious and logical reason for this is your coffee is not fresh. Offerings such as decaf or single origin selections are often less popular than other roasts. They tend to hang around longer, so they can become easily unusable if you are not careful.

Timing is everything

When you grind coffee and allow it to sit more than fifteen (15) minutes, like any food product, it begins the process of breaking down. Coffee loses color and the CO2 that produces crema in your shot dissipates.

Everyone who has had a fountain beverage knows what I mean. You can no longer call it fresh or palatable unless you’re desperate.

Ground coffee that is not fresh will always pour and taste less than desirable. Most serious coffee businesses have turned to on-demand grinders to ensure product quality, however, baristas continue to see flat shots but only occasionally.

On-Demand Grinders ensure freshness

Endure with me, I just need to do a short explanation for those who are not familiar with on-demand grinders. On-demand grinders save espresso businesses a tremendous amount of money because grounds do not sit in a grind chamber to deteriorate while waiting to be used.

The Nuova Simonelli G60 on-demand grinder is a popular choice for many who serve a coffee to accommodate a more specific clientele. It is smaller and for low volume, so it is a less expensive machine. It is a designed to grind and dose only the amount you need and only when you need it.

On-demand grinders are a logical choice for business owners, but you may be wondering why your coffee is still occasionally pouring like the CO2 has disappeared?

First pulls are rarely fresh

You may be surprised to learn that all on-demand grinders have something in common. Regardless of if it is an expensive high-volume or a smaller grinder like the G60, they all retain grounds around the burr area. All pulls from any grinder will draw first from these grounds.

When your grinder has sat for more than fifteen (15) minutes or overnight for that matter, your first pull will always be unusable. These grounds should be placed into your waste bin as quickly as possible to avoid keeping your customers waiting.

Latte – Cappuccino Steam Wand Maintenance

This article is reprinted with permission. It was originally published by the Espresso Service Network

There are two types of steam wands. Manual wands which operate with a mechanical valve and automatic heating and frothing wands which always operate with a solenoid (electro valve). There are some exceptions. For example, the Slayer Steam espresso machine models are manual wands but operate with solenoid valves. The same can be said for the Rancilio Specialty RS1 espresso machine. There are also different types of actuators such as buttons, knobs, and levers. Regardless of the type of steam wand you work with, all need some type of maintenance.

Periodic Rebuild

If your machine has a manual wand and a mechanical steam valve you will need to have your valves rebuilt periodically. Mechanical steam valves have moving metal and plastic parts that are lubricated to help them shift. Over time, friction dissipates the lubrication that keeps these parts moving smoothly. The internal components of a valve that does not receive maintenance will eventually begin to grind together. It is important to have these parts lubricated at all times.

Your steam valve also contains O-rings and seals. Over time, the heat produced by your machine will cause these wear n’ tear parts to become brittle. Gaskets will no longer seal properly. Your steam wand will either start leaking through the front of the valve or through the wand itself. Even worse, your steam valve could stick open causing a huge safety hazard, potentially harming someone.

Timely Maintenance vs Damaging Equipment

Preventative maintenance must be completed timely and on a regular basis. Many valves if maintained may never need replacement, however internal parts that experience times of unprotection will become prematurely worn or damaged. Some things cannot be fixed if worn too severely.

Steam Actuators

Regardless of if you operate your steam wands with a lever or knob, they too are moving parts that will also need lubrication.

Timing Services

Typically, servicing your steam valve and actuators should be part of your annual preventative maintenance, but it really depends on your usage, the design of your wand and the materials used by your manufacturer. Some higher volume businesses should have maintenance done bi-annually and others can go as much as two years. If you are operating at medium to high volume, I would recommend you have maintenance completed by your service technician at least once a year.

Electro or Solenoid Valves

For wands utilizing a solenoid valve, the only time you will need to address your steam wand’s electro valve is when it is time to replace it. Solenoid valves either work or do not.

Solenoid valves should be replaced when they are still functioning to avoid emergency repair service. Some valves can be rebuilt but for most others, your service provider will need to make an educated guess on when to replace them before unexpected failure.

The goal for your service technician is not to replace any electro valve (i.e., brew, hot water, steam) prematurely but not to have them fail causing your business to come to a grinding halt. The more history your service provider has in working with a specific type of valve will decrease your chance of equipment failure and overpaying for maintenance.

Electro valves are expensive and can run anywhere from one hundred to five-hundred dollars. Steam wands using a solenoid valve need no maintenance, but your steam wand will still need service.

Your Pivot Joint

Lastly, regardless if you have a manual or an automatic heating wand, both will maneuver on a pivot joint. You need to care for this area by replacing specific seals, springs, or spring holders. The convenience of caring for your pivot joint is that you do not have to turn your espresso machine off to perform this maintenance.

Each manufacturer is different on how long the materials they use will last and of course, it will also depend on how much use and movement your steam wand experiences. A good model for maintenance for manual wands is to service your pivot area every time you rebuild your valves. For those operating with electro valves, service your pivot area every time you have maintenance completed on your espresso machine.

We hope you found this espresso equipment maintenance tip helpful. if you have comments or suggestions on improving the information in this article, please forward your remarks to solutions_usa@esnservices.org. They will be appreciated and warmly received.

What You Should Know Before You Buy Commercial Espresso Equipment

This article is reprinted with permission. It was originally published by the Espresso Service Network

As a retailer of commercial espresso equipment, the Espresso Service Network interacts with all types of equipment buyers. We speak with the experienced searching for specific features to those just starting out, yet to brew their very first shot. Regardless of an individual’s experience with espresso equipment, it is important to understand that operating and maintaining commercial espresso equipment is unlike other industrial appliances. The equipment is designed to produce multiple outcomes which require technicians to have a specific education, however, service technicians are not required to have any training to work in the industry so the cost and level of service greatly vary between retailers. If you care about your coffee, you will want a technician that can do more than replace parts but will also have a basic understanding of coffee brewing and water treatment pertaining specifically to espresso equipment. For you to be satisfied with your equipment and the level of service you receive, your service technician should share the same intensity or in some cases, a lack of intensity for your coffee as you. Whether this is your first time, or you already have experience owning and operating equipment, below are points every buyer should know before purchasing commercial espresso equipment.

PARTS

Manufacturers to Avoid

Commercial espresso machines imported into the U.S. can be distributed independently or by a branch of the manufacturer.

Some importers carry a limited parts inventory and offer little support to technicians. Your technician should have a solid resource to reach out to when seeking parts and assistance for your equipment in order to make it easier for them to be responsive to your repair needs.

Keep in mind that the longer your equipment is inoperable the more detrimental it is to your business. Customers who are forced to go elsewhere for their coffee do not always return.

If a service company does not have a trusted source for parts, an equipment owner may experience longer equipment downtime and will pay additionally for their technician to research and track down parts.

Tip: Shop with manufacturers who have a main distribution center that offers technician training, equipment manuals, and a full catalog of parts.

Original Equipment Manufactured (OEM) Parts

It is important that your service provider only utilize original equipment manufacturer (OEM) parts during your equipment’s warranty period.

If you have a component failure, and your service technician uses an after-market part, if that part fails too, your manufacturer will not cover its replacement and may void your complete equipment warranty. Some manufacturers will not sell parts to an unauthorized service company and if they do, they may not offer them discounts which means you could pay higher part prices during your equipment ownership.

A service company may choose not to become an authorized service provider with a manufacturer for several reasons.

• They may have had a bad experience with the manufacturer’s equipment or customer service department.

• A service company must meet the requirements of the manufacturer to become a sales and service agent, which may include purchasing a minimum parts inventory and technical training.

• The high cost to meet these requirements may not be reasonable if only a few units of the manufacturer’s equipment are being sold in their service area and they have not been assigned a service agreement with another retailer.

• The manufacturer may also choose to limit the number of service agents selling and servicing their equipment in one area.

• A service company will almost always have the option of purchasing aftermarket parts, but some key parts will only be available through the manufacturer.

Do not assume one service company will be able to provide you with the same level of service as another.

Tip: Before purchasing equipment, speak to several local service companies in your area about the manufacturers they are authorized to support.

EQUIPMENT SPECIFICATIONS

Equipment Accommodations

Equipment comes in all sizes and configurations. Before you purchase your equipment, consider the size, weight, plumbing, and electrical needs.

Specification sheets are available with any equipment retailer.

• Is your counter strong enough to hold the combined weight of your equipment?

• Is your counter large enough?

• Will you need a plumber or electrician to meet the equipment’s requirements?

In most cases, once shipped commercial espresso equipment is non-refundable or may have restocking fees associated with a return,

Tip: Before you buy make sure you can meet all the needs of your equipment to function safely and to its fullest potential.

Place Your Order Sooner than Later

Currently, manufacturers are struggling to keep equipment in stock.

Select your equipment at least eight (8) weeks in advance and even earlier if you plan to have your equipment customized.

If necessary, your retailer will work with the manufacturer to have your equipment held complimentary until you are ready for installation. If you ship your equipment prematurely, you could end up paying warehousing fees to the service company.

Tip: Do not wait till the last minute to place your equipment order.

WARRANTIES

Manufacturer Warranty

This warranty indicates that the manufacturer of your equipment is responsible for replacing parts and materials that are defective, but that is all.

Your manufacturer warranty does not include your technician’s labor or any travel expenses to have your machine evaluated, nor does it cover shipping for any parts to be replaced in your machine.

The length of a manufacturer warranty can vary, typically from one to two years with some electronic parts extending beyond that.

Tip: Take the time to understand the details of your manufacturer warranty.

Service and Warranty Agreement

Your warranty is important, especially in the first few months of your equipment’s operation.

Your equipment service agreement should identify your service provider, if different from your retailer, and cover your and your retailer’s responsibilities regarding installation, labor and travel warranty, and the shipping and handling of warranty parts.

Your responsibilities will most likely come with penalties if not met. Having everything in writing is important when you need to reference what your agreement covers and the complimentary services that came with your purchase.

Tip: Avoid additional charges, by working with a retailer that places your service and warranty in writing.

Other Services and Warranties

Most manufacturers require retailers to include a one-year labor warranty to back their part (manufacturer) warranty. This separate warranty is usually referred to as an extended warranty.

A labor warranty will pay your technician to repair or replace parts the manufacturer determines to be defective. Your labor warranty will also cover your technician’s evaluation time but only if the manufacturer ultimately determines that the breakdown was caused by a defect in their material or workmanship.

This extended warranty is included because the expense of labor to support the manufacturer warranty can generally be more costly than most part failures that would cause your equipment to become inoperable. The cost of commercial espresso repair can be costly when a technician’s labor for evaluation and travel is incorporated in a warranty repair.

Tip: Shop with retailers that include a travel warranty, complimentary preventative maintenance, and other free services.

RETAILERS

The Best Retailer is the Most Knowledgeable

If possible, work with a retailer that is an expert in the service and maintenance of commercial espresso equipment. It does not have to be the company that does your actual service.

Purchasing from an experienced sales and service company will protect you from technician mistakes, unfair labor charges, and missed warranty issues that are not obvious to a less conscientious technician.

Tip: Plan to work with your retailer for the life of your machine.

Buying Direct from the Manufacturer

Manufacturers are set up to sell their equipment direct to you, but at the same time, they do not want to necessarily compete with their distributors.

You will most likely pay top dollar for your equipment if you purchase directly from the manufacturer. You’ll also be sending your business outside your community which is never helpful for any retailer.

Tip: Look to local roasters and service companies for better equipment pricing with add-on services such as complimentary preventative maintenance.

Buying Online

Retailers with websites offer convenience and a pleasant shopping experience but are out of reach when warranty and service issues become complicated.

The Espresso Service Network is an online retailer so we are kind of dinging ourselves here but do check out our Service Provider Sales Program. This explains how we partner with the best service companies in your area to bring you the best service possible.

Finding the Best Retailer Takes Effort

The commercial espresso equipment manufacturer offers you several places to purchase equipment so do not get drawn into common and ridiculous sales pitches like, “It’s a workhorse, you can’t go wrong.”

Avoid taking the advice of just one source. Take the time to visit local espresso bars, taste their coffee, and ask who maintains their machines and what they like about their equipment. Make note of the manufacturers being used. If you like the coffee of a café’ or drive-thru and their equipment appears to be in good working order, their service provider may be a good lead.

Contact the equipment manufacturer of the machines being used in your area. You can find the contact information of many manufacturers on espressoservicedirectory.com. Let them know what community you plan to serve your beverages and ask who they recommend you purchase their equipment from.

Tip: Search for the best retailer with the most knowledgeable technicians and the best comprehensive service in your area.

Buying from a Roaster

Although most roasters are educated in coffee, equipment service is a separate industry with parts management, after-hours, and emergency service.

Many roasters only offer limited repair services with just fundamental diagnostic assistance. Some roasters will also discontinue your service if you stop purchasing their coffee.

Buying from a Local Service Company

The espresso industry does not require any special license to work as a technician. Purchasing from your local service provider does not guarantee a stellar service experience. You may be better off purchasing from a sales and service company one hundred miles away rather than working with someone that is just starting out or whose business is focused on another type of equipment such as refrigeration.

GETTING THE BEST SERVICE

Do Not Settle on a Poor Service Company

If you purchase from a retailer that will be subcontracting your installation and repair services, do not assume you will be receiving the best service in town.

Most experienced service companies sell equipment and do not always accept customers who choose to purchase elsewhere. If you cannot purchase directly from a local sales and service company, do not allow your retailer to select an inadequate service provider.

Tip: Plan to work with your service provider for the life of your equipment.

Subcontracted Service Companies

If your retailer is subcontracting your service, ask your retailer for a written agreement with your service provider.

Service agreements offer insight to what your service provider cannot or is unwilling to provide you. Your agreement with your service provider can also reflect the level of service you are receiving compared to other retailers.

Without an agreement, service companies are not obligated to provide you any services pertaining to your warranty or purchase including utilizing OEM parts, storing your equipment, or training you in maintenance, operations or programming just to name a few.

Tip: Avoid low level service companies that will not acknowledge their responsibilities in writing.

FINER DETAILS

Manufacturer Warranty Expiration Date

Most manufacturer warranties do not start at installation but rather when the manufacturer ships the equipment from their warehouse.

If you are purchasing from a retailer and the equipment is coming from their warehouse, the warranty on your equipment is already aging.

Tip: If you must purchase a machine that is not shipping direct from the manufacturer, ask your retailer to cover defective materials and parts in your service agreement if your manufacturer warranty expires early because of this technicality.

Manufacturer Direct Shipping

If possible, avoid purchasing in-stock equipment from a retailer.

Manufacturers are always updating software, repairing glitches, and modifying their equipment designs.

This will also ensure that you are not purchasing equipment with an expiring manufacturer warranty.

Tip: Have your equipment shipped direct from the manufacturer to ensure you are purchasing the newest generation of your equipment model.

FINAL TAKEAWAY

Select a retailer that understands espresso repair and is prepared to monitor the services completed on your equipment so that warranty issues are identified and taken care of promptly and before your warranty expires.

If you must purchase your equipment from someone that will need to subcontract your installation and repair services, make sure you have a written agreement with your service company so that your technician will be accountable to your business.

Once you are in business, your espresso equipment will be vital to your success. Take the time to do your research and choose the retailer best suited for your business.

Espresso Grinder Burrs: What is the Difference?

This article is reprinted with permission. It was originally published in the Coffee Technicians Guild.

–By Chase Lemos, Nouva Ricambi USA

Not all burrs are created equal. The design of the burr coupled with the material composition can change a lot about how the coffee turns out. Burrs have a usable lifespan and then need to be resharpened or thrown out. Burr life depends on a number of factors – metal composition, geometry of the cutting surface, size of the burr and the type of coffee being ground.

Metal composition

Most grinders come standard from the factory with oil quenched steel burrs. These are the most common type of burr out there and can be identified by their matte-grey appearance. These standard burrs have a tough outer shell of hardened steel with a soft inner core. They can be thought of like an M&M chocolate candy. The shell is hard to protect the inner steel. The life of these burrs is determined by the harder outer layer, once you reach the soft inner steel they wear very quickly and need to be replaced. In a 64mm burr this happens around the 650-750lb mark.

The next level is the Extended Life burr. These burrs are reasonably priced and offer an improvement in life over standard burrs (as the name suggests). Extended Life burrs can be recognized by the increased shine and more silver color (over the standard burr). These burrs have a hard(er) outer shell with a soft inner core. Due to the process with which they are ‘quenched’, they have a lower friction coefficient than standard oil quenched burrs which results in less wear on the burr per measure of coffee ground. The more advanced process used to harden the outer layer does add to the cost of the burr right out of the factory. These burrs, in 64mm, will last for around 1,000 to 1,100lbs.

Above Extended Life burrs are the Chromoly Steel burrs. These burrs are moderately priced because the price of the raw steel is more than the Standard or Extended Life burrs. The advantage of this step-up in raw material is a burr that is tougher and hard all the way through. 64mm Chromoly Steel Burrs can grind around 1500-1600lbs of coffee before they need to be replaced.

Tool Steel burrs (D2) are the cream of the crop in terms of uncoated burrs. These burrs start to cross into the pricey category. They are hard all the way through with an excellent hardness rating. This category of steel was specially formulated to have high abrasion resistance allowing it to wear slowly. The draw-back is that it must be heated to a very high temperature to be workable. This requires special equipment for the burr manufacturer and is part of the reason these burrs carry a premium price tag. These burrs in 64mm will grind 2400-2500lbs before they need to be replaced.

To get any more production out of a set of burrs, you have to start coating the steel with other super-substances. The most common one is Titanium Nitride (TiN). It is identifiable because of the gold coloration the TiN coating puts on the burr. In order to apply the coating, the steel must be super-heated which can cause most steel burrs to warp. Because of this, it is necessary to use Tool Steel as the base for TiN burrs. This results in a very hard steel with a very low friction coefficient. This means that you first wear out the TiN and then you wear out the Tool Steel creating a 64mm burr that will grind 3,000-3,100lbs before it needs to be changed.

Ceramic burrs will go about the same duration before they need to be changed. The marked difference between TiN and Ceramic burrs are the thermo-properties of the material. The steel will hold a lot of heat while the ceramic will shed heat fairly quickly. There are differing viewpoints as to which is preferable. The first thought is that ceramic burrs are preferable because they will not heat up and so they shouldn’t ‘cook’ the coffee during grinding when compared with the steel which will get hot after several subsequent grinds. The second thought is exactly the opposite – the steel is better because it holds the heat. This means that the heat is captured in the burr and is radiated away while the grinder sits idle while the ceramic burr won’t hold any heat (but will create heat) meaning that the heat must be absorbed by the grinder motor or by the coffee. This would mean that ceramic burrs will have a larger ‘cooking’ effect on the coffee than steel burrs. We do not yet have enough evidence to prove which way of thinking is correct. I would argue that the correct answer probably depends on your volume of coffee per hour. Given that the goal is a perfect cup of coffee first and worrying about grinder longevity second, I would think that steel will perform better at light to moderate usage while ceramic burrs will cause less damage to the coffee during especially heavy traffic hours.

Burr Geometry

The geometry of the cutting surface can completely change the way that grinder burrs work in your grinder. There are several issues that burr geometry can either cause or remedy. The first of these is when a set of burrs causes your grinder to clog. This is generally due to the primary cut of the burr (the largest cut on the inside of the burr). When your primary cut is too choked off (the angle formed off the radius line by the cut is too great) can result in clogging with darker coffees.

The second issue that stems from burr geometry is your grind speed. Grind speed changes from one burr to another due to the angle at which the secondary and tertiary cuts meet. The outer two cuts form a scissor with their other half (the other burr) – the steeper the angle at which the ‘scissors’ meet the faster the burrs will grind but the more load you will put on the motor and the capacitor. Alternatively, if the angle is shallow, you will grind more slowly but it will be easier on the motor and capacitor. The outfall depth (if you line up the teeth of the burr so you can see the hole created by the matched low point in the tooth pattern, the hole created is the outfall) will impact grind speed at the cost of fine/course ratios. Larger outfall depths will allow a faster grind with a wide variation between fines and courses while a smaller outfall depth will allow a greater consistency from fine to course particles at the cost of grind speed due to the alignment and subsequent misalignment of the cutting channels.

The size of the burr will influence the amount of work a set of burrs are able to do. The larger the burr, the more spread out the job of breaking down the bean will be and the longer the burr will last. Larger steel burrs are able to accumulate more heat but will take longer to cool down once they get hot. A burr with larger cutting beds will accumulate less heat as it grinds because it will be able to more gradually step down the bean particulate (won’t have to break it all at once).

Coffee Roast Effect on Longevity

As coffee roasts, it releases water, expands and becomes less dense. This means that roast level will also impact the life of the burr. A darker roast will be a less dense bean, and therefore will be easier to ‘cut’. As such, dark roasts will wear down burrs less quickly. While lighter roasts have more retained water in the bean and will present a greater challenge to break down. Therefore, lighter roast coffees do dull burrs faster than darker roasts. White coffee is still very hard and will wear out the burr much more quickly than the stated wear rate would suggest. White coffee may also have a negative impact on the life of your capacitor and motor in your grinder.

Rocks are another object that are rather difficult for espresso grinders to break down. The steel may be able to make some progress, but will generally become unusable if the rock is allowed to remain in the grinder for any period of time. The rock may also simply bind the burrs together and not allow them to move past one another which could cause a broken sheer pin or eventually a worn-out motor. Rocks are not recommended to be run through your espresso grinder (neither are screws, or any other foreign object).

Spices are another thing that some customers like to feed into their espresso grinders. Black pepper, cinnamon and other tasty morsels wreak havoc on burrs and grinder components alike. Espresso grinders are highly adapted to evenly and effectively break down coffee beans, they were not designed with spices in mind. In theory, a grinder may be able to break down these substances, however, the fine particulate may end up in unintended locations and ruin the grinder. The spices may also leave behind a non-coffee flavor that will season subsequent shots (as will flavored coffee).

Burr Wear

New burrs are quite sharp and can ‘cut’ the coffee differently during their brand-new ‘break-in’ period than they will after they have accumulated some wear. Because of this, burrs will have to be constantly recalibrated, especially in the first couple weeks of use. Your espresso may pull faster through a newer set of burrs because the particulate will have a sharper edge to it causing it to settle less well into its neighbors and allow for more avenues of water travel.

Alternatively, dull burrs are not good for quality espresso either. Dull burrs take longer to grind a measure of coffee and will squish the coffee more than they will cut it. This will cause them to heat up more quickly. This crushed coffee will be more like peanut butter and can cause increased clogging and longer shot times. The crushed coffee will look almost round under magnification causing it to tamp poorly (increasing channeling). The best espresso can be achieved using a burr that is between brand new and worn out (don’t worry this is about 99% of a burrs life span).

To test burr sharpness, drag the top of a fingernail over the leading edge of the burr. If the burr catches and pulls or digs into the nail, the burr is still plenty sharp. If the burr does not bite, then it isn’t biting into the coffee either and needs to be replaced.

Burr Maintenance

Burrs do like to be maintained. All they really need is to have the grind chamber occasionally vacuumed out and to have a product like Pully Grind run through the grinder at least once a week (maybe even daily, depending on coffee volume). This regular maintenance will improve the flavor of the coffee by pulling out putrid coffee oils that are literally rotting in your grind chamber. The fix isn’t terribly expensive, in dollars or in time, and can help prevent clogging.

Instant rice can be run through a grinder to much the same effect as a specialized chemical cleaner, but can void the manufacturer warranty on a grinder. If you are cleaning a grinder for a client, please do not use instant rice. Please use an appropriate product that has been approved by the grinder’s manufacturer. This will protect both your client and yourself and may even allow you to sell another product to your regular customers.

As with previous articles in this series, this is meant to be informational, and the ultimate test is always the coffee in the cup. However, dull burrs will always make the coffee taste a little ‘off’, so encourage your customers to care for them and replace them when necessary.

8 Tips for a Great Grind Every Time

- Particularly for home machines, do not let the same beans sit in the bean hopper for several hours or even worse, overnight. Besides adversely affecting the bean taste, bean oil will coat the inside of your hopper and burrs. Oil-covered burrs are dull and will not grind properly.

- For commercial shops, disassemble the bean hopper, adjustment ring, and top burr at least weekly. Wipe the bean oil from the bean hopper (do not use a scratch pad as it will permanently damage the hopper), and clean the burrs and the area surrounding the bottom burr.

- Clean the burrs before grinding a different type of bean. Don’t forget to remove the previous bean grinds from the coffee chute (the area underneath the burrs to where the grounds emerge) and closer. It’s hard to evaluate a new roast if the grounds contain remnants of the previous bean.

- When cleaning your burrs, lightly run your thumb against the sharpened edges. If the burrs are sharp, they should grab your thumb; as the burrs dull, they will feel smoother.

- Always replace burrs in pairs.

- Look at your coffee grinds periodically. If the burrs are sharp, the grinds will be the same size. Dull burrs tend to smash the coffee grounds; ensure the grinds don’t smell burnt.

- If you use flavored beans, the flavor oils tend to remain in the grinder long after the bean is gone. A thorough grinder cleaning is the only way to prevent your expensive light roast from tasting a lot like your daughter’s hazelnut-flavored bean.

- For the best flavor, use your coffee within 10 minutes of grinding.

The importance of a quality grinder

The coffee-making process consists of moving water through the ground coffee, you should pay close attention to those two items. Regardless of how much money you spend on an espresso machine, using improperly ground coffee and/or bad-tasting water will produce lousy-tasting coffee. It would be a true statement to say that the coffee grinder is probably the most important piece of coffee equipment you have.

A grinder’s sole function is to produce consistently sized grounds. Without that consistently sized ground, your high-dollar coffee machine will never make a great cup. There are numerous, quality commercial and home grinders that produce great coffee grounds. However, you won’t find a good, new, commercial grinder for $150 or a good, new, home grinder for $25. The price for a good commercial coffee grinder starts easily at the $1000 range and goes up. Burr grinders are the key to a good grind for espresso drinks. Blade grinders chop the bean into inconsistent sizes – and although not ideal, can be used for cold brew, French press and other immersion methods. Burr grinders can be calibrated to grind consistently and the size of the grind can be easily adjusted.

Once you’ve adjusted your quality grinder to produce the grounds that best suit your coffee, don’t assume that setting will never change. You will find that humidity effects your espresso shot time. Higher humidity usually requires a little finer grind, while lower humidity may require a slightly coarser grind.

The grinder burrs are what actually cut the bean and they have a finite lifespan; as the burrs wear, you must adjust the grind setting to maintain the same grind. Depending upon several variables [cutting area (i.e. 58mm, 63mm, 71mm), shape (flat or conical), and the manufacturing material (steel or ceramic)], burrs will grind anywhere from 600 to 40,000 lbs of beans before requiring replacement. Check the manufacturer’s literature to find your model’s burr rating.

Manufacturer’s recommended burr ratings for some of the more popular commercial grinders:

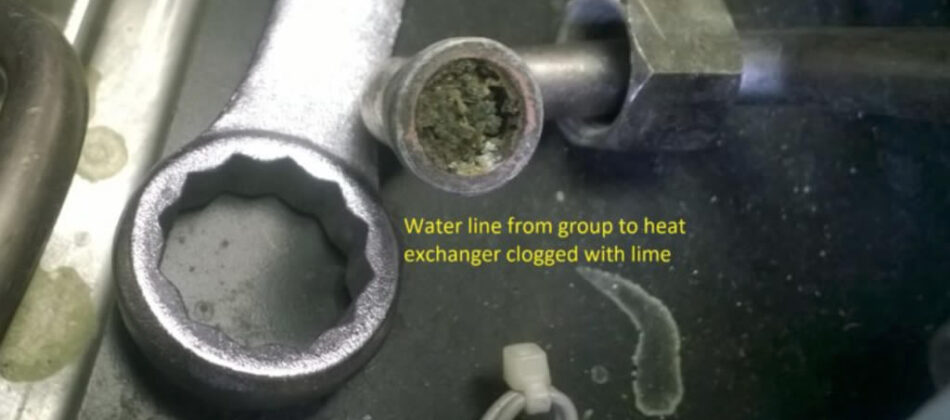

Oh, the things we have seen!

We’ve talked about the damage that lime buildup can do to your machines. Here are images showing just what it can do. Click the < > arrows on the photo above to see more.

Sad fact: Every espresso machine manufacturer’s warranty specifically excludes hard water-related repairs.

What can you do? An easy, and economical solution is to have an in-line softener added to your espresso unit. This little goodie will save you hundreds of dollars. We carry in-line softeners for your convenience. You can install them yourself, or we’re available to install them for you. Just reach out to us to get pricing for your system or to learn more. We’ve got your back!

Can you repair my cappuccino machine?

Great question – and we’re asked this often! The wand that makes cappuccinos and lattes is a part of your espresso machine!

We repair espresso machines!

So the answer is a resounding, YES! 😊 Just reach out to us and we’ll get your cappuccino machine in working order again!

Tips on hard water and lime

Our advice will save you hundreds of dollars on repairs.

Don’t Neglect Your Water

Water is probably the most neglected part of making coffee. If you don’t like the taste of your water, you won’t like the taste of your coffee. Most tap water is fine—whether it be well water or city water—but we recommend you test your water periodically. In most instances, relatively inexpensive water treatment can make a big improvement in your coffee. For example, if your water has a distinctive chlorine or other taste, there are numerous inexpensive, easily installed, taste & odor filters available

Check Your Water Hardness

Besides taste, the biggest water concern is its softness; hard water is the enemy of anything that heats the water. When an espresso machine boils water, the minerals in the water fall out and accumulate in your boiler—just like your home hot water heater.

Once in your boiler, that accumulated lime reduces your boiler capacity, can reduce heating element effectiveness, and may cause your boiler to overfill. Water carries small pieces of lime throughout the machine where it blocks flow meters, keeps valves from closing, and clogs lines.

We aren’t exaggerating when we say 85-90%+ of our repair business is directly attributed to lime.

Watch Out for Lime Buildup

Is your business in Indiana?

Central Indiana sits on top of some of the world’s best limestone, which is a good news/bad news situation.

The good news is Indiana limestone is so desirable it was used to build the Empire State Building.

The bad news is that the same limestone ensures we have extremely hard water. Any central Indiana water used to make espresso must be softened.

Choosing to save a little money today—by not softening your water—will cost you much more money later.